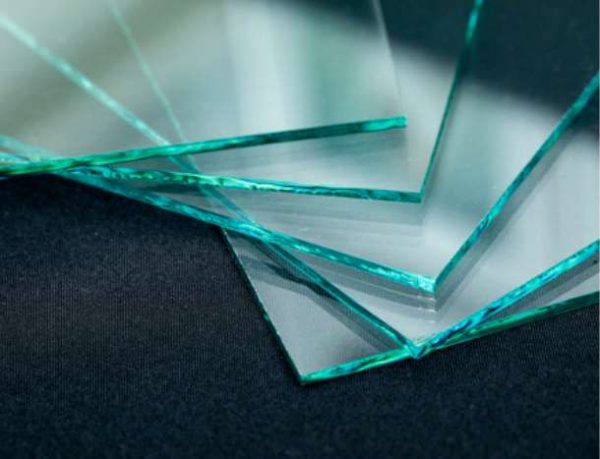

Glass/ Transparent Materials

HIGH PRECISION MICROMACHINING FOR GLASS AND TRANSPARENT MATERIALS

OUR PROCESS:

The JASPER family is a suitable choice for everyone who requires high precision and high-speed marking, cutting, welding or 3D structures.

The ultrashort lasers offer tremendous advantages in processing transparent and brittle materials. A laser pulse is absorbed in nonlinear process inside the material – but only in the very localized volume around the focusing point. The surround material stays unaffected, thus heating or cracking may be eliminated, allowing for fine and very precise 3-D structures to be directly built inside.

Nowadays, glass is widely used in various products like smartphones/mobiles, laptops, televisions, medical devices and other consumer electronics.

Work with the right micromachining manufacture and micromachining laser today.

Femtosecond laser processing offers cost-effective services and solutions such as laser drilling, laser cutting, laser wielding, laser marking, surface structuring, polishing, engraving, and so on.

Contact us for a FREE QUOTE, or to obtain more info on specific application-related projects.